coriolis flow meter troubleshooting

Check the output wires connection according to the wiring diagrams in Appendix. This force is called the Coriolis force.

Ultrasonic Flow Meter Explained Working Principles Realpars

Planning Installation Manual October 2021 20002158.

. Since Coriolis type flow meters measure mass. 2 check for leaks around the flow meter inlet and outlet connections. Practical or Hands on Operating and Parameter setting on Coriolis Flowmeter 2.

Coriolis Flow Meter Troubleshooting If no leaks are present bring the system up to the operating pressure. Performance of Coriolis Flowmeter Day 2 1. The Unit has been calibrated and is operational.

Entrained air requires additional energy to drive the meter tube as the entrained air absorbs some of the energy. Make sure you have 24 VDC power and sufficient current ability to drive resonating circuit for the Coriolis Mass Flow Sensor. The effect of static pressure on the meter calibration can also be a.

Problem Scenario Will be simulated and Participants should solve it 3. If none of the troubleshooting questions or. Learn about the methodology for troubleshooting Coriolis Flowmeters by creating the correct problem statement to achieve resolution.

Coriolis Mass Flow Meters designed specifically to provide optimum performance in low-flow applications. We have installed a Coriolis mass flow meter on a 2 process line. In order to ensure the measurement accuracy of the mass flowmeter and long-term stable and regular work the mass flowmeter should be installed reasonably used correctly and strengthened daily maintenance and management.

This means you can trust the mass flow measurement as long as the drive gain is any number less than 100. SOURCES OF TROUBLE FOR FLOW METERS. Coriolis flow meter troubleshooting.

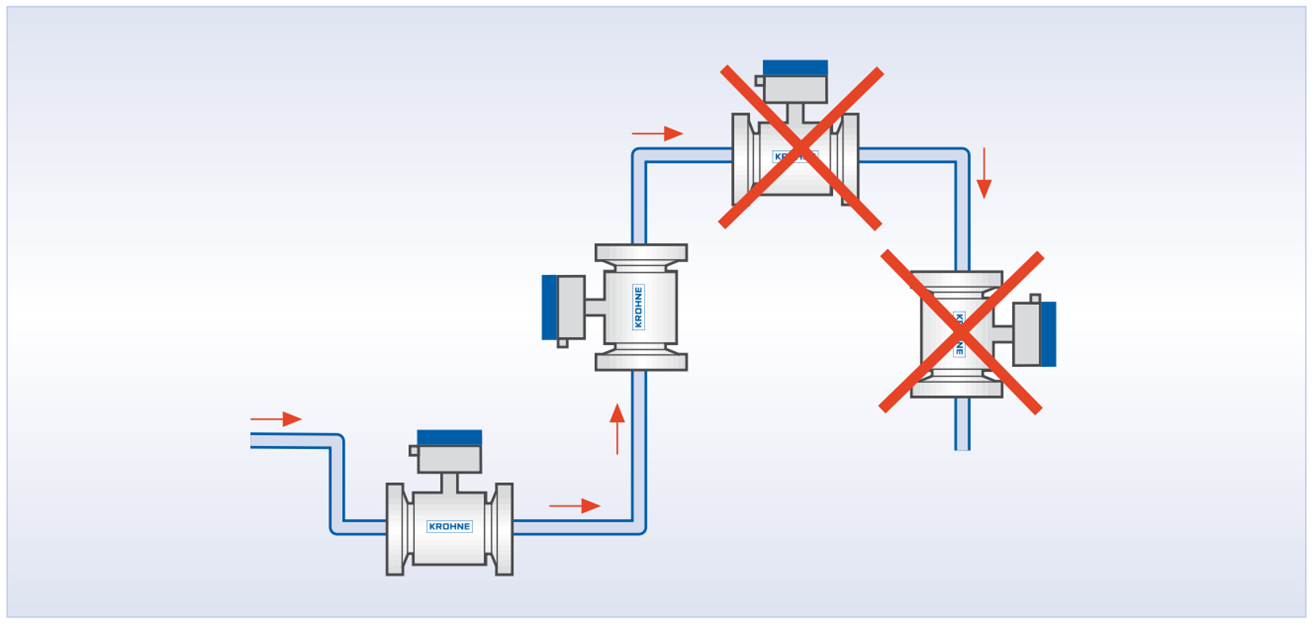

Gases should flow downward. Flow Rate And Pressure Flow through a pipe can be determined using the Darcy-Weisbach equation or one of the other equations for irreversible pressure drop. Among various types of flow meters Coriolis mass flow meters are the most.

Any drive gain value below 100 means that the flow tube vibration in the Coriolis meter is still at the precise target amplitude distance apart at the peak of cycle. These equations are generally. Coriolis flow meter calibration performed with high-pressure natural gas can improve measurement and reduce uncertainty.

A comparably sized Coriolis meter can run upwards of 9000 or more. Micro Motion Advanced Phase Measurement application manual. For those who have evaluated Coriolis meters in the past this may be the not-so-secret dirty little secret.

Coriolis meters are multivariable devices that directly measure mass density and temperature. Coriolis flow meters can calculate actual volumetric flow rate from the independently measured mass flow rate and density using the equation below where Q is the volumetric flow rate and r is the fluid density. With an electromagnetic type flow meter wear and clogging are minimal due to the free-flowing structure of the unit.

These oscillations are recorded by sensors fitted at the inlet and outlet of each tube. This is causing the density and hence the flowrate to be erratic. The problem is reportedly related to the meter drive coil running out of energy.

A Coriolis flow meter consists of two parallel tubes that are made to oscillate using a magnet. Most other flow meter technologies produce volumetric flow as the raw output which is typically converted into a standard volume. It does not act directly on the body but on the motion of the body.

But Coriolis meters are not immune to problems. It allows for measuring various fluids eg. If the sensor is installed in a vertical pipeline liquids and slurries should flow upward through the sensor.

Oct 30 2000. Since coriolis meters are unaffected by varying flow profiles users need not worry about. No operator shall be permitted to perform procedures relating to installation.

These guidelines are designed to aid in troubleshooting and operation of provers that are in use together with Micro Motion Coriolis meters. It comprises a single flow tube which is considerably smaller in size than the conventional U-Shaped flow meters. Contact an Equilibar application engineer to help find the right back pressure regulator to improve the accuracy of the Coriolis flow meter in your application.

Karman vortex models the slurry may cause axial wear and clogging. Q m r. This principle is used in Coriolis flow meters.

Although Coriolis meters are accurately calibrated with water by meter manufacturers that calibration can increase uncertainty when meter operations are transferred to natural gas. Introduces the elements and factors that cause problems for flow meters. Learn about the methodology for troubleshooting coriolis flowmeters by.

Back Pressure Regulators can be used to prevent bubble formation in Coriolis flow meters. Learn about the most common issues users face with regards to configuring and troubleshooting of Coriolis flow meters. Keep the sensor tubes full of process fluid.

They dont require straight runs of pipe or flow conditioners. How to verify and test a Coriolis Mass Flow Meter for proper operation. How to Troubleshoot Coriolis Mass Flowmeter 1.

Our problem is we have air bubbles entrained in the liquid. Motion Inc explored recent advancements in Coriolis meter diagnostics. 224 Super Bend The Super Bend coriolis mass flow meter is used in a wide range of applications to accurately measure the flow.

Having problems with a mass flow meter - Coriolis. Coriolis mass flowmeters daily maintenance. These oscillations are recorded by sensors fitted at the inlet and outlet of each tube.

And they can be stable over a long period of time. Micro Motion ELITE flow meters are high- precision Coriolis flow meters that are often used in the oil and gas industry in conjunction with volume provers. They dont have moving parts.

Wrong connection of the output wires to the coriolis gas flow meter or secondary devices. Proving results may vary if unstable. A one-inch line magnetic flow meter and transmitter for example can be had for 3000 or less.

For flow meters that obstruct flow ie. Check the computers port used to connect the flowmeter to the computer through digital interface. For halting flow through the sensor with a single valve install the valve downstream from the sensor.

Flow lab understanding Multiphase Flow practically and problems caused by Multiphase flow and how to overcome. When using coriolis mass flow meters to measure liquids flow with entrained air especially viscous liquids the meter reports inaccurate readings. The Tactical Flow Meter Coriolis Mass flow meter consumes a max of 15 watts of power or at 24 VDC we need at least 620 mA of current per Coriolis Mass Flow Meter.

Conductivity Analyzers Interview Questions Answers Interview Questions And Answers This Or That Questions Interview Questions

This Coriolis Mass Flowmeter Is Corrosion Resistant Chemical Engineering

Industrial Instrumentation The Working Principle Of Coriolis Flowmeters Electronic Engineering Engineering Technology

3 Dirty Little Secrets About Coriolis Flow Meters

Preventing Bubbles With Coriolis Flow Meters Equilibar Fluid Control

Micro Motion Coriolis Meter Characterization And Configuration Using Prolink Youtube

How To Zero A Coriolis Meter Using The 5700 Transmitter Display And Prolink Youtube

Mass Flowmeter Coriolis Supplier Manufacturer Mass Flowmeter Coriolis Manufacturer Supplier Flow Measurement Flowmeter Supplier Abb

Proline Promass E 100 Coriolis Flowmeter Endress Hauser

How To Verify And Test A Coriolis Mass Flow Meter Tactical Flow Meter

Pros And Cons Of Coriolis Flow Meters A Solution To Bunker Disputes Safety4sea

How To Perform In Situ Verification Of A Flowmeter Wwd

Coriolis Mass Flow Meter The Piping Engineering World

How To Verify And Test A Coriolis Mass Flow Meter Tactical Flow Meter

Calibration In Process Instrumentation Influences In Practical Use Krohne

The Basics Of Flow Measurement With Coriolis Meters Part 2

The Basics Of Flow Measurement With Coriolis Meters Part 1

Turbine Flow Meter Explained Operation And Calibration Youtube